Roof penetration is a passage unit used for installation of steel ventilation shafts at the points of their passage in roof coverings of various types and purposes of buildings. This article will talk about the various features of roof penetrations, as well as their composition and varieties.

Roof penetration is a passage unit used for installation of steel ventilation shafts at the points of their passage in roof coverings of various types and purposes of buildings. This article will talk about the various features of roof penetrations, as well as their composition and varieties.

General purpose roof penetration is placed on reinforced concrete sleeves. The fastening of such penetrations is carried out with the help of nuts screwed onto the anchor embedded bolts, and the bolts are provided in the glasses initially.

As a material for thermal insulation, mineral wool slabs are used, additionally wrapped with fiberglass on the outside.

The mechanical control of the valve is carried out using a special auxiliary mechanism, which is adjustable for two modes of operation:

- "Open";

- "Closed".

Important: the valve actuator must not be placed below the ring sleeve, which may lead to the accumulation of condensate on it.

Most often, roof penetrations are installed in the ventilation system of buildings and general-purpose buildings, which use two types of ventilation:

- Natural ventilation;

- Forced ventilation system.

During the design phase of a building, the choice for a particular system is influenced by a number of different conditions, such as humidity levels, minimum and maximum air temperatures, and many others.

The penetration of the roof is calculated using two parameters:

- The angle of the roof slope;

- The distance from the ridge to the penetration.

The design of the passage assembly also includes a branch pipe, which is connected to a support flange that acts as a fastener and is used to connect the roof penetration with a reinforced concrete cup.

The lower end flange is used for fixing valves or air ducts, and the upper one is used for a shaft with a round section. To fix the braces on the roofing, special brackets are used, and in the shaft - clamps.

The main characteristics of roof penetrations

The roof passage equipped with a manual drive is used in a stable mode of operation that does not require periodic switching of the mode.

A hand drive typically includes the following components:

- Portcloth;

- Control device;

- cable;

- Counterweight.

To provide additional waterproofing of the roof covering during installation of the system, a skirt can also be used as a constituent element of the system. If necessary, roof penetrations are also equipped with a special condensate collector, which is welded to the branch pipe.

It allows you to collect moisture coming from the air and gas mixture, preventing it from penetrating into the roofing, causing its destruction.

In addition, a special list of conditions has been developed under which the passage units will be operated. In accordance with this list, the climatic version of a particular unit is selected, as well as additional options.

For example, whether it will use a universal sealant for roof passages and, if so, in what quantity.

For the manufacture of roof penetrations, black steel is most often used, the thickness of which is from one and a half to two millimeters.

In addition, the passage units can be made of two types of stainless steel:

- Stainless steel 0.5 mm thick;

- Stainless steel 0.8 mm thick.

Currently, eleven standard options for the diameter of roofing penetrations are produced. In addition, the manufacturer can produce passage assemblies with a diameter different from the standard ones, designed for use in various conditions.

Roof penetration is primarily intended for high-quality removal of the ventilation system on the roof of a house or building. This improves air ventilation and creates more suitable conditions for it in each specific situation.

For use in the ventilation system of buildings, today there is also a wide range of supply systems, the installations of which are equipped with good sound insulation.

The composition and manufacture of roof penetrations

Standard roof penetrations usually consist of two parts, each of which, in turn, includes an internal and external contour.

Each of these circuits is equipped from the inside with a special insulation layer made of basalt fabric, which is highly resistant to temperature extremes and ignition.

The nodes of the passage through the roof are most often made of black steel with a thickness of one to three millimeters, which is then covered with heat-resistant black enamel, which allows the penetration to withstand temperatures up to 600 degrees.

In addition, in accordance with certain operating conditions, as well as the technical capabilities of manufacturing and the wishes of the designer or the developer himself, penetrations can be made of stainless steel. The thickness of the material in this case can be from one to two millimeters.

In the manufacture of roof penetrations, it is imperative to take into account three important parameters:

- Roof slope angle;

- The thickness of the inter-roof space and do-it-yourself roof rafters;

- roof materialused for the manufacture of the rafter system, the ceiling and the roof itself.

In order to prevent penetration through the node of the passage of water formed as a result of precipitation, special "layouts" are used.

They are a metal strip, on which there is a hole for the chimney and a special flanging on the sides.

For the manufacture of "layouts" polyester is most often used, the color of which is selected in accordance with the color of the roofing material. The layout is located on the gap between the ridge and the passage node, which should be covered by it from all sides.

Useful: depending on the cross section of the air duct or chimney connected to the roof penetration, it can be made with the same cross section.

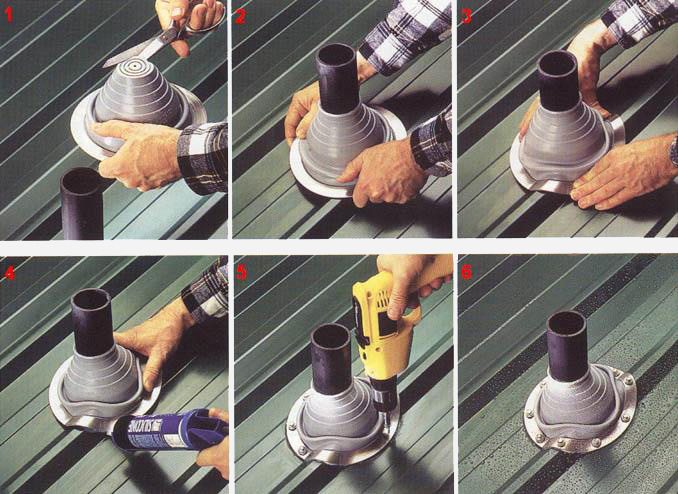

Here is an example of mounting a passage through the roof (the sequence of actions is shown in the figure):

- The seal ring is selected so that the diameter of the resulting hole is approximately 20% smaller than the diameter of the pipe drawn through the roof;

- The seal is stretched along the pipe, if necessary, the tension can be facilitated with a soapy solution;

- The sealant is pressed against the roof in order to give it a shape that matches the shape of the base. Tools can be used to firmly press the edges of the flange to the roof surface;

- A special sealant is applied under the flange;

- The flange is attached to the base with screws screwed in at a distance of about 35 mm from each other;

- Roof penetration installation completed.

That's all I wanted to talk about roof penetrations, we hope that this information will be useful in the implementation of the chimney and ventilation on the roof.

The use of roof penetrations allows you to do it efficiently and not cause any harm to the roof directly.

Did the article help you?