The node of the passage through the roof of the air duct is a metal structure used in the installation of steel ventilation shafts in the locations of the passages of ceilings of various types and purposes of buildings. This article will talk about what passage nodes are, what types of them exist and how they are installed.

The node of the passage through the roof of the air duct is a metal structure used in the installation of steel ventilation shafts in the locations of the passages of ceilings of various types and purposes of buildings. This article will talk about what passage nodes are, what types of them exist and how they are installed.

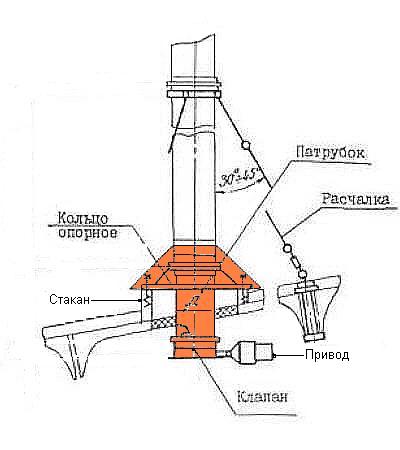

The air duct passage assembly through the general-purpose roof is most often placed on reinforced concrete cups, its fastening is carried out using anchor bolts and nuts provided in the cups initially.

The main purpose of the nodes of the passage through the roof is the transportation of air flows and environments that do not have chemical activity, the temperature of which does not exceed 80 degrees, and the relative humidity is not more than 60%. The production of passage units for exhaust ventilation shafts is carried out in accordance with GOST-15150.

Roof penetrations in the form of thermal insulation material are made using high performance mineral wool boards, additionally wrapped with fiberglass on the outside.

To implement the mechanical control of the valve, a special mechanism is used, configured for two main operating modes:

- "Open";

- "Closed".

Important: the control mechanism must not be placed under the ring sleeve, as it will collect condensate there.

Installation of nodes of passage through the roof

The roof pass-through assembly is most often installed in the ventilation system of buildings and structures intended for general use, where either natural or forced ventilation is used.

The choice of a specific ventilation system at the stage of technological design of a building is carried out taking into account a whole list of conditions, such as humidity, ambient temperature, etc.

To calculate the node of the passage through the roof, only two parameters are enough:

- Distance from roof ridge;

- Roof slope.

The roof penetration also has such a specific feature as the presence in the design of a branch pipe connected to the support flange, which acts as a fastening element that allows the passage unit to connect through the roof with a glass of reinforced concrete.

In addition, the lower end flange of this branch pipe is used to fasten air ducts or valves, and the upper one is used to fasten a round shaft. For fixing the braces, various brackets and clamps are used.

Varieties of passage nodes

In modern construction, the following options for manufacturing nodes of passage through the roof are used:

- Passage nodes do-it-yourself roofing with missing valve;

- Passage units equipped with a valve, equipped with manual control;

- Insulated or non-insulated passage units with an actuating controlled mechanism.

Passage nodes, characterized by a manual drive, are used in a stable mode of operation that does not require multiple switching.

This manual drive includes the following items:

- management sector;

- cable;

- tailor's cloth;

- counterweight.

In addition, a skirt can be used to install the system, which also provides additional waterproofing of the coating. roofs.

It is allowed if necessary, for example - when moisture falls out of the gas and air mixture, and additional equipment of the passage units with a condensate collector welded to the branch pipe.

For mechanical control of the valve, a special MEO-type actuator is used, the regulation of which is carried out using the “open” and “close” commands.

To avoid damage to the actuator, it must not be installed in close proximity to a condensate trap or ring coupling.

At the moment, the following materials are used for the production of passage units through the roof for various purposes:

- steel is black, the thickness of the material is from one and a half to two millimeters;

- stainless steel, material thickness is 0.5 mm;

- stainless steel 0.8 mm thick.

Eleven standard options for the size of the diameter of the passage through the roof are produced.

In addition, the manufacturer may decide to produce a passage assembly with a non-standard diameter in the case of using mineral wool boards as insulation of the passage assembly.

Various options for the nodes of the passage through the roof are marked with the following designations:

- From UP1 to UP1-10, passage units are marked, in which there are no valves and rings collecting condensate;

- From UP2 to UP2-10, passage units are designated, equipped with a valve equipped with manual control, but with a missing ring that collects condensate;

- From UP2-11 to UP12-21 designate passage units equipped with both a valve equipped with manual control and a condensate-collecting ring;

- From UP3 to UP3-10, pass nodes are marked, in which a valve equipped with a tag design is used, but a ring is not used;

- From UP3-11 to UP3-21 designate those passage units that are equipped simultaneously with both a valve using mechanical control of the marking design and a ring designed to collect condensate.

Did the article help you?