On a suburban area, in addition to a residential building, there is an urgent need for additional buildings: a garage, a recreation area, a summer kitchen, a barn, etc. If you build a canopy with your own hands from metal, it can successfully serve as one of them.

This building is quite simple in terms of engineering, design and construction. It will be durable and strong, but its price is much less than a building that has walls.

Advantages of metal

Light metal structures have the following advantages.

- High level of strength.

- Durability - the service life is about 45 years.

- Structures can be given a variety of shapes.

- Quick installation - within 4/5 days.

- Resistant to changes in humidity and temperature.

- Reliability of pairing of all elements.

- Fire resistance.

- Canopies made of metal structures have aesthetics and visual lightness.

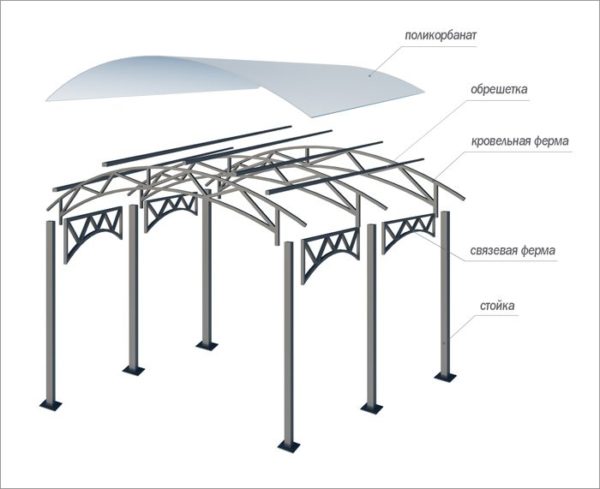

Structure design

First of all, you should design a canopy. During this process, the shape of the structure and its roof are selected.

Shape and material

Steel is a flexible material, so structures can be given any shape: round, square, rectangular, polygonal, oval, etc.

The roof of the canopy can have the following popular configurations:

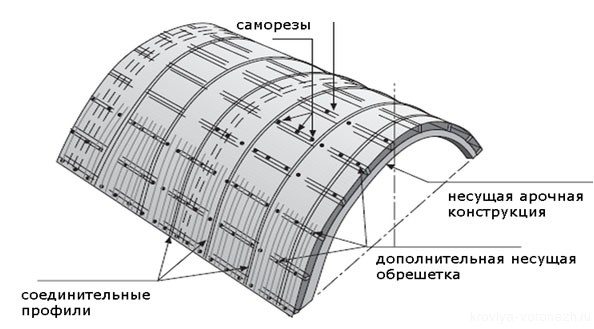

- arched shape. Practical and beautiful. On such a roof, snow does not accumulate, wind loads are not terrible for it, thanks to its excellent aerodynamic properties.

- Smooth pitched roof. It looks like an enlarged visor over the porch. A canopy with such a top can be both isolated and attached to the house.

- Smooth gable shape is the most practical. Precipitation (rain, snow) on such a structure does not linger.

- The wavy roof is highly aesthetic and, in addition to practical functions, also decorates the site..

- Concave gable shape imitates the roofs of oriental buildings and carries a touch of exoticism. Excellent rain water removal.

Note!

The curved design of a metal canopy is quite difficult to manufacture.

For this you will need a pipe bender.

Another option is to order bent elements in the workshop.

Roof selection

For a metal structure, such roofing materials are most often used.

- Polycarbonate plates can be cellular or monolithic. The latter option is more durable and expensive. The cellular analogue is flexible, it is possible to create curvilinear shapes from it. The material has a wide range of colors and different levels of light transmission.

- Canopy from a metal tile or a professional flooring. These covers are simple and easy to install. Be warned that these materials make a lot of noise when it rains.

- Asbestos-cement slate tested for decades. It is inexpensive and has good strength.

- Reinforced PVC tarpaulin. Such a cloth is quickly stretched and removed. Possesses different light transmission.

Implementation of settlements

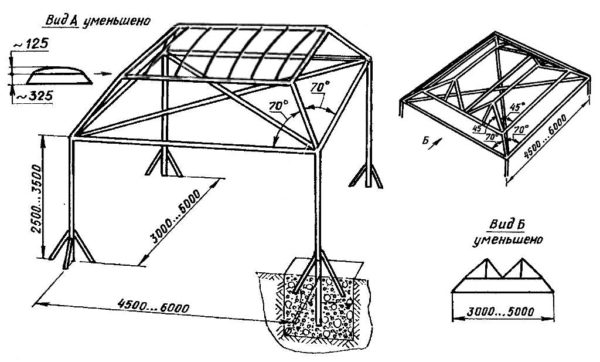

First you need to choose a place to mount the canopy. It should be located most conveniently, based on its purpose.

Note!

Next, you need to determine the dimensions of the future building, based on your needs.

Then the materials for the canopy are selected and their strength characteristics are calculated taking into account the resulting loads.

After that, drawings of metal canopies are drawn up, and the amount of the required material is calculated.

Tools and materials

For work you will need:

- profiled pipes made of metal, of different sections - for the frame;

- selected roofing material;

- self-tapping screws for metal;

- polymer profiles for polycarbonate;

- crushed stone, cement, sand for concrete.

It is necessary to purchase material with a margin of 10%, taking into account waste.

Also prepare the tools:

- welding machine;

- grinder;

- drill;

- bayonet spatula;

- screwdriver;

- plumb and building level.

Canopy construction

Now you can get started.

Installation of supports

- It is necessary to build a canopy on a flat area, which should rise slightly above the ground and have a slope for the outflow of water. Remove vegetation from the site and level it.

- Next, install the supports. To mark the points under them, use the do-it-yourself metal canopy drawings made. Dig four holes, at least 60 cm deep. Install poles in them. It must be done evenly, so use a plumb line or level when working. Pre-fix the racks with stone supports or wooden blocks.

- Then stir the concrete and fill the holes with it. The proportions of sand, water, cement and gravel in the solution should be as follows: 3/1/1/3.

- Leave the racks alone for 3 days for sufficient curing of the mixture.

Frame installation

Next, metal structures for polycarbonate canopies are installed. Before welding operations, check the correct position of the tops of the racks. Take measurements along the diagonals and the perimeter, taking into account the height of the supports.

Then you have to act like this.

- Horizontally weld profiled piping to the tops of the posts.

- Elements should be fixed on it roof frame.

- When you have finished installing the canopy frame, clean up the welds and seal all openings.

- Further, the instruction recommends covering the metal with anti-corrosion primer and painting.

- After that, you can lay the roofing material.

Conclusion

Installing a canopy on your site is not so difficult. This can be done by any summer resident who knows how to use a welding machine.A metal structure can be used as a garage, a summer kitchen, a sports and playground, an outbuilding. The video in this article will continue her theme.

Did the article help you?