| Illustrations | Recommendations |

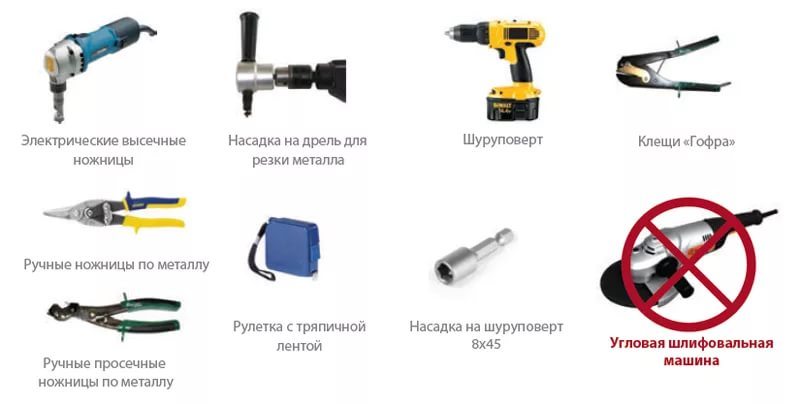

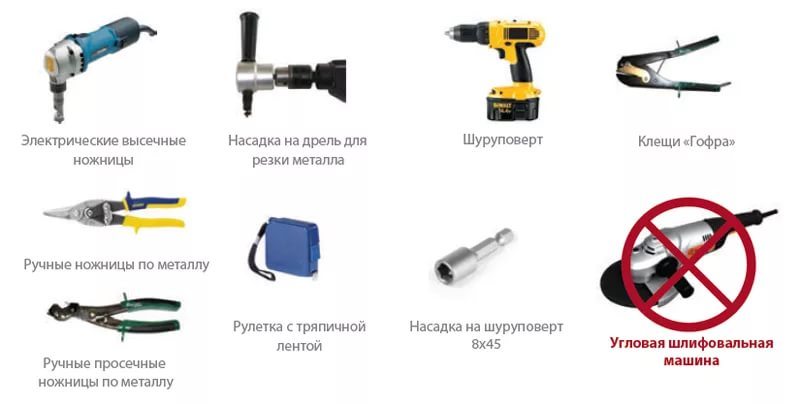

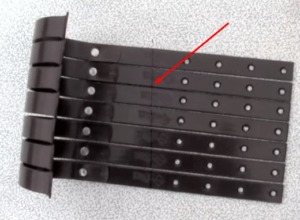

| Tools. The photo on the left shows the minimum set of tools, in addition to it you will need: - stapler;

- Mounting knife;

- Knife for cutting thermal insulation;

- Template for the crate.

|

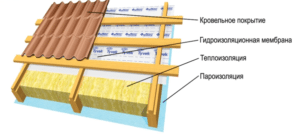

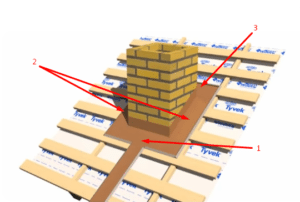

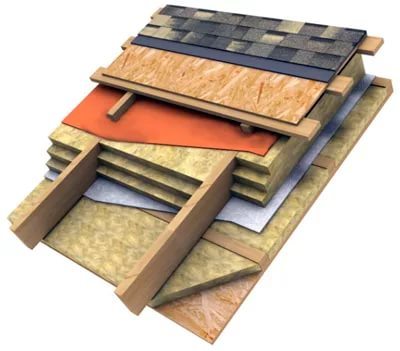

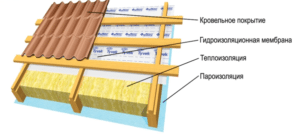

| roofing cake. The scheme of the roofing pie is simple, but it is important to follow the order of installation. |

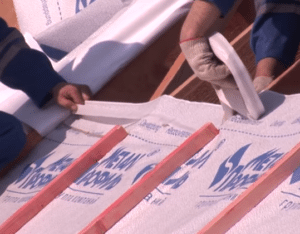

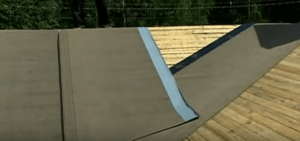

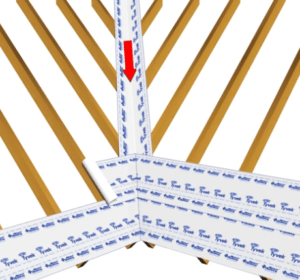

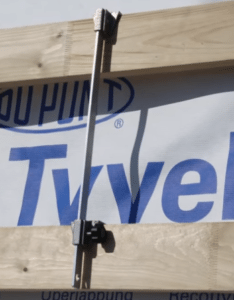

| Waterproofing. First, waterproofing is laid on top of the rafter legs: - First, we roll out and fasten the canvas in the valley with a stapler;

- Then, with an overlap, perpendicular to the rafters, the canvases are laid from the bottom up.

|

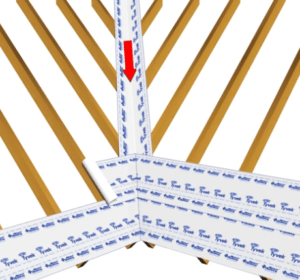

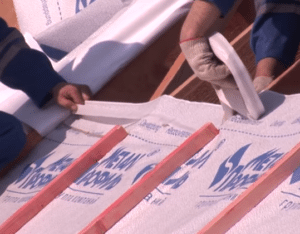

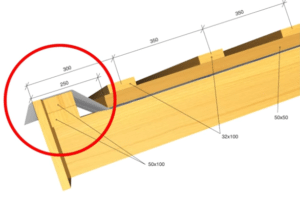

| Horizontal canvases they are nailed to the rafters with 50x50 mm bars, and the overlap is glued with double-sided adhesive tape. On both hydro and vapor barriers, the recommended amount of overlap is usually marked with a dotted line.

|

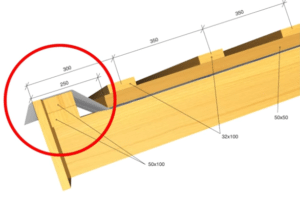

| We fill the crate. - First, 2 bars of 50x100 mm are nailed along the edge, and a waterproofing sheet is released and attached on top of them;

- Further from the bottom up, the boards of the crate 32x100 mm are stuffed;

|

| - Lathing step is selected according to the step of the imprint of the metal tile, in this case it is 350 mm, we control it using a template;

|

| - In the skate area 2 boards are packed closely.

|

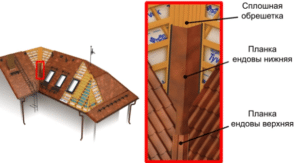

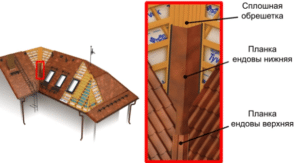

| Arrangement of the valley. The valley is the corner joint of two roof planes. It consists of a bottom and top bar. The main amount of water will drain along the bottom bar, and the top bar is more for decoration. |

| bottom rails are screwed to the crate from the bottom up with self-tapping screws with a press washer. The overlap should be 100–150 mm. The top bar is screwed after fixing the sheets of metal. |

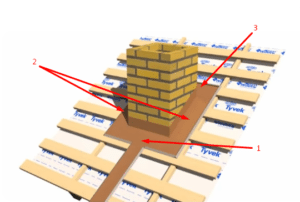

| We go around the brick pipe. Around the pipe, we need to mount straight sheets with flanging: - First, a sheet is installed from below, it has a chute for draining water (tie), which is directed to the drain system or valley;

- Next, two side sheets are attached;

- The top sheet above the pipe is installed last.

|

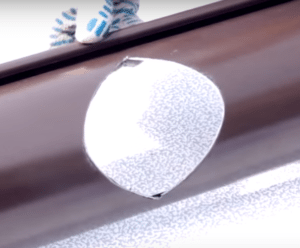

| - For tightness, before installing the sheet, a groove is cut along the perimeter of the pipe;

- Then this groove is cleaned and filled with sealants;

- Next, we insert the bend of the sheet into the groove and fix the sheet with self-tapping screws on the crate.

|

| After installing the metal tile, it will be necessary to fix the top plate with self-tapping screws, similar to the valley. |

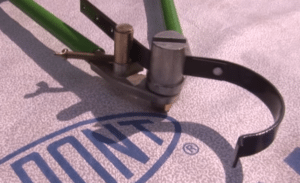

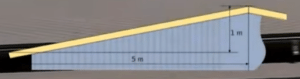

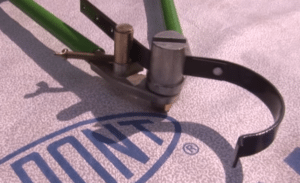

| Gutter system. It is desirable to mount this system before covering with metal tiles: - First, we mark the holders, they are installed in increments of half a meter and should have a slope towards the funnel of 3 mm per 1 running meter;

|

| - Further along the markup, we bend the holders with a strip bender and fasten them to the edge of the crate;

|

| - We cut a hole in the gutter for the funnel;

|

| - We insert and fix the chute into the holders. By the same principle, side plugs, drain funnels and connections between the sectors of the gutter are attached.

|

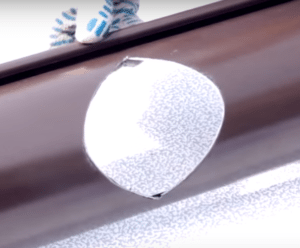

| eaves plank. - This bar is hooked onto the edge of the gutter and fixed on the crate with self-tapping screws in increments of about 1 m;

|

| - A double-sided tape is glued on top of the bar and the edge of the waterproofing sheet is fixed on it.

|

| Cutting metal tiles. Sheets of metal tiles can be cut with scissors or special nozzles. After cutting, the edge of the cut is treated with polymer paint. Cutting sheets with a grinder is strictly prohibited.

|

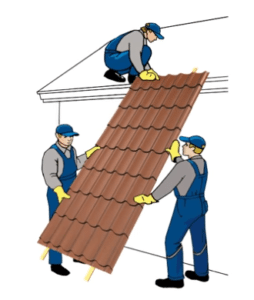

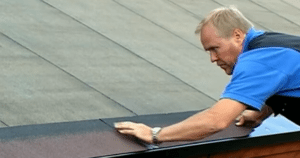

| Roof installation. The metal tile is a delicate thing and you need to lift it carefully along the pre-knocked guides. |

| Fit. If the length of the sheet is equal to the length of the roof slope, then the sheet is immediately aligned along the ridge and fastened with self-tapping screws. - Self-tapping screws will be driven into the bottom of the wave and are staggered across the wave.

If you cover the roof with slate, then slate nails are hammered into the top of the wave.

|

| - If you cover the roof from left to right, then the edge of the second sheet is placed under the edge of the first;

- If on the contrary, from right to left, then the next sheet overlaps the previous one.

|

| If your sheets are less than the length of the slope, then the roof is sewn up in sectors, as shown in the diagram. |

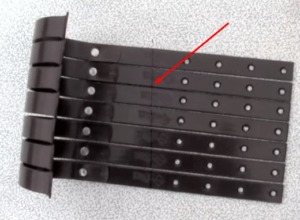

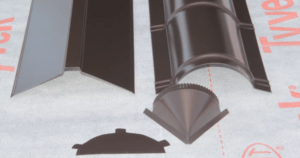

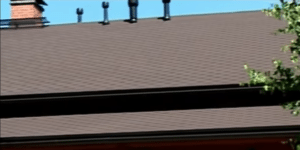

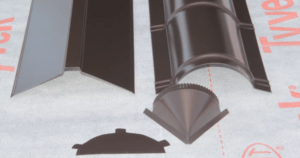

| Mounting the skate. Ridge pads are flat and semicircular, but there is not much difference in installation. - First, a cap is attached to the end of the lining with self-tapping screws;

|

| - A polymer ridge seal is placed under the bar, after which it is fixed to the roof with self-tapping screws through one wave.

|

| - For the arrangement of the ends of the roof, there are special strips that are fastened from the bottom up with overlapping screws.

|

| We mount thermal insulation. As thermal insulation, I recommend using dense basalt wool slabs. The slab is cut 2–3 cm larger than the opening and inserted between the rafter legs. |

| There is no need to fix the plates at this stage. If you gave a good overlap, then they will stay in their places anyway. |

| We mount the vapor barrier. Thermal insulation boards are hemmed from below with a vapor barrier sheet. It will not allow the basalt wool slabs to be saturated with moisture, plus it will keep them in the opening. As you can see in the photo, the canvas is attached with a stapler. Move from bottom to top.The joints of adjacent canvases are overlapped and glued with double-sided tape. The installation of the insulated roof is over, now it only needs to be sheathed from the inside with some kind of finishing material, for example, clapboard. |