What is vapor barrier, why is it needed, and how is it performed? I've thought about this before. Now, having gained experience in this matter, I will accurately convey the technical points, and step by step I will describe the technology for installing the vapor barrier.

Why moisture protection is needed

Vapor barrier is a combination of various methods for protecting heat-insulating materials and building structures from the penetration of steam and, as a result, from the loss and absorption of condensate (Footnote 1).

Why is vapor barrier needed at all? As you might guess, its meaning is to protect surfaces from steam. Moreover, we are talking not only about visible steam, but also about moisture, which is always present in the air.

Inside the dwelling, the level of humidity is almost always higher than outside, which is explained by cooking, washing and taking water procedures. Since the steam moves towards the cold - outside, excessive moisture can significantly reduce the life of building structures and the effectiveness of the insulation.

Protection is needed in the following cases:

- When insulating walls from the inside with mineral wool. As you know, the level of vapor permeability and moisture absorption of mineral wool is quite high.

Therefore, the lack of vapor barrier can lead to the accumulation of moisture inside the insulation. This, in turn, will lead to a decrease in the effectiveness of the insulation, dampening of the walls, the formation of fungus, etc.;

- When insulating frame structures. Vapor barrier is necessary for frame walls, wooden floors and pitched roofs, not only in the case of using mineral wool insulation, but also polymer ones, which have zero vapor permeability.

The fact is that the zero vapor permeability of thermal insulation leads to the fact that all moisture rushes into the elements of the wooden frame. As a result, the tree quickly becomes unusable;

- When insulating floors. Vapor barrier in this case allows you to protect the insulation from rising steam.

In the case of using mineral wool inside the partitions, vapor barrier can be omitted, since there are no temperature drops in the partitions that can lead to the formation of condensate.

materials

As we found out, the vapor barrier should not allow air to pass through, which carries moisture. Therefore, the vapor barrier film should not be confused with waterproofing, which often has the ability to pass air.

Currently, the following materials are used for vapor barrier:

Polyethylene

Polyethylene films are the cheapest option for vapor barrier. As a rule, polyethylene film is used for waterproofing floors and walls.

Kinds. Polyethylene films come in several types:

- Single layer. The cheapest, but not durable, and also unstable to mechanical stress;

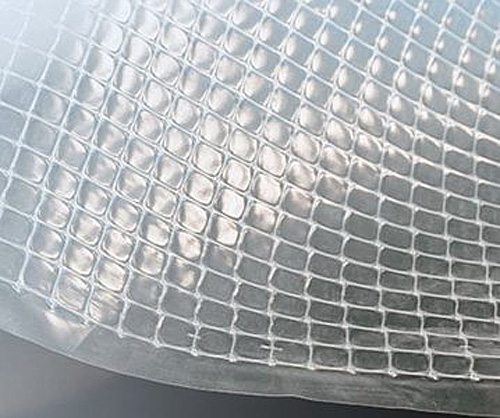

- reinforced. They are a three-layer material. The middle layer is made of fiberglass mesh.

Thanks to the reinforcing layer, the film has higher strength and durability;

Below is a table from the manufacturer of roofing materials with a brief description of the main parameters of the vapor barrier reinforced film (Footnote 2)

| Material | 4-layer reinforced film made of polyethylene with a reflective layer of aluminum. |

| combustibility | G4 highly flammable (GOST 30244-94) |

| Flammability | B2 moderately flammable (GOST 30402-96) |

| Breaking force | 450 N/5 cm |

| Vapor permeability | 3.1 x 10-6 mg/m*h*Pa according to GOST 25898-83 |

| differential resistance fusion Sd | Over 150 m |

| Heat resistance | from - 40 °C to + 80 °C |

| Weight | 180 g/m² |

| Roll weight | 13.5 kg |

| Roll size (flat spare) | 50 m x 1.5 m (75 m2) |

- Foil. The main feature of these films is the ability to reflect heat.

Price:

| Film type | Price per roll |

| Reinforced 4x25 m 100g/1 m2 | 2750 |

| Reinforced 2x10 m 140/1 m2 | 750 |

| Single layer 3x100 m 120 microns | 4600 |

Polypropylene

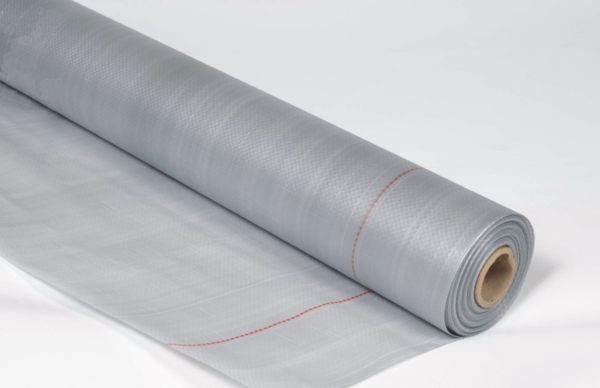

Polypropylene vapor barrier films are the most popular, as they are superior to polyethylene in all respects. In particular, they are stronger, more durable, and resistant to UV radiation and temperature extremes.

Another feature is that these films usually have a two-layer structure. As a result, one of the sides has a rough surface.

This is done so that the villi retain moisture on the surface of the coating and thereby allow it to evaporate. Beginners often ask which side to put the vapor barrier on?

The material is laid with the smooth side to the insulation, and the rough side - to the cladding. True, if you mistakenly fixed the canvas with the rough side to the insulation, this is not a critical mistake, since in any case the material does not allow moisture to pass through.

Therefore, a ventilation gap is required between the film and the finishing material.

Price. Below are the prices for popular vapor barrier materials that have proven themselves well:

| Brand | Price |

| Stroybond B 70 m2 | 635 |

| Izospan B 70 m2 | 1 140 |

| Nanoizol B 70 m2 | 770 |

| Metal profile H 96 1.5x50 m | 1800 |

| Axton d 35 m2 | 615 |

The nuances of installing vapor barrier films

Basic Rules

So, we figured out the types of vapor barrier materials. However, the quality and effectiveness of steam protection depends not only on the type of material, but also on the quality of its installation.

Therefore, finally, consider the technology of laying vapor barrier. But, first I will give some important installation rules:

- The vapor barrier is attached from the side of the housing. Since the steam flows from the inside of the room to the outside, the vapor barrier is always installed from the inside, which makes it possible to provide a sealed circuit;

- The film must be correctly positioned relative to the insulation. Which side to lay the vapor barrier to the insulation, I have already said above - smooth for thermal insulation, rough for finishing;

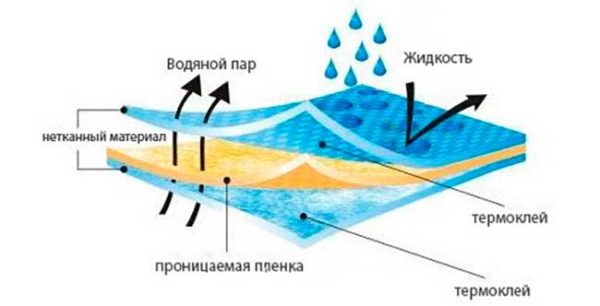

- From the outside, the insulation is protected by waterproofing. It is almost impossible to provide complete protection of thermal insulation from steam. So that penetrating moisture can leave the insulation, it is closed on the back side with a waterproofing diffusion membrane.

This material is able to pass moisture only in one direction; - The vapor barrier must be airtight. To prevent the film from passing steam, it is necessary to seal the places of its contact with the frame, and also glue the joints of the films with double-sided adhesive tape.

Mounting technology

We will consider the technology of film installation using the example of vapor barrier of frame-type walls. This procedure can be divided into several stages:

Instructions for the use of vapor barrier is as follows:

If a wooden house is insulated from the inside, it is necessary to provide a ventilation gap between the walls and the waterproofing membrane. In addition, holes must be made in the walls themselves from below and under the visor. These measures will allow moisture to go outside and prevent dampening of the walls.

This completes the installation of the vapor barrier. I must say that the roof, walls and ceiling are covered with vapor barrier according to the same principle, so we will not consider each case separately.

Conclusion

Now you know how much vapor barrier is necessary, as well as how and how to do it correctly. Additionally, I recommend watching the video in this article. If any nuances caused you questions - write comments, and I will be happy to answer you.

Did the article help you?