When planning the arrangement of the roof with ondulin in advance, we always try to determine how much material is needed. It often happens that we have to buy additional roofing, because we made an incorrect calculation, or when buying we are faced with the problem of the lack of material of the appropriate color or size. To avoid this, it is necessary to take into account the size of the ondulin sheet, the parameters of which are described in this article along with the secrets of installation.

Coating characteristic

Roofing ondulin is used in the construction or repair of roofs on residential, commercial or industrial facilities.

Roofing ondulin is used in the construction or repair of roofs on residential, commercial or industrial facilities.

Such qualities as an attractive appearance, a wide range of colors, a convenient size of ondulin, flexibility, a long service life, ease of installation make the material popular for arranging the roofs of canopies, shopping pavilions and cafes.

Due to its low weight (approximate load of 3 kg per 1 sq.m), ondulin can be laid on the old roofing during roof repairs. The warranty period from the manufacturer for this material is 15 years, and the actual service life reaches 50 years.

This roofing refers to a reliable and durable material that does not contain harmful substances (unlike asbestos slate).

Technical specifications

The production of this roofing consists in pressing cellulose fiber into sheets, the shape of which resembles ordinary slate, and coating them with bitumen.

The top layer of ondulin is coated with hardening resins and mineral pigments.

This technology defines:

- protective characteristics of the material;

- aesthetic appearance;

- long service life.

When ondulin is made, the sheet size of almost all manufacturers has a standard value. The manufacturer has the right to allow an error in size from 2 to 5 mm.

This roofing has the following parameters:

- length 2 m;

- width 95 cm;

- thickness 3 mm;

- wave height 36 mm;

- the weight of one sheet is 6 kg.

When determining the required amount of material, many take into account only the overall dimensions, forgetting that transverse and longitudinal overlap is carried out during installation.

In this regard, the useful area of ondulin is reduced to 1.6 sq.m.Considering that you are equipping a roof with a slope of more than 15 degrees and an area of 100 sq.m, you need 63 sheets (100 / 1.6) and 8 ridge elements.

Attention. These calculations can be taken into account if a gable roof of a simple form is being equipped, without complex architectural elements.

Installation secrets

When purchasing ondulin - the sheet dimensions of which have a standard value, each person tries to familiarize himself with the rules for its installation in the attached instructions for the material.

In this article, we want to focus on some of the secrets of editing:

- The coating is fixed with nails supplied with the material. Ondulin dimensions determine the use of 20 fasteners per sheet. Otherwise, the sheet may not withstand wind loads;

- Installation ondulin roofs carried out at a temperature not exceeding 30 degrees;

- When installing the crate, the slope of the roof should be taken into account (with an increase in the angle of the slope, the step of the boards of the crate increases);

- If you need to move along previously fixed sheets, you should step on the ridge;

- Sheets tend to stretch a little, so laying must be done carefully (without stretching). Otherwise, the coating will look like waves;

- During laying, the parameters and the number of overlaps should be strictly observed. Mounting ondulin - the size of the sheet is 2 m long, the overlap is 10-15 cm in length, and 1 wave in width. The overlap is made only in one of the four corners of the roof.

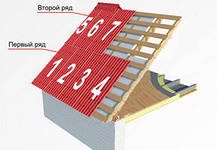

Advice. It is recommended to start laying the second row with half of the sheet coverage. A large overlap is formed, which determines the reliability of the roof.

Application Benefits

Ondulin is used in many countries due to its advantageous properties:

- sheets withstand up to 300 kg of snow load per 1 sq.m;

- material on the roof provides wind resistance of 200 km/h;

- the ability to absorb noise reproduced from hail and rain;

- resistance to temperature extremes;

- provides resistance against bending;

- resistance to impact, acid and mechanical stress;

- the bearing capacity of this material is 650 kg per 1 sq. m due to the small waviness of the sheet and the multilayer composition;

- ondulin sheets are strong enough due to the formation of layer-by-layer crossing fibers during pressing;

- water resistance;

- operation of ondulin can be carried out at a temperature of -40-+80 degrees.

Ondulin has a low level of water absorption, therefore, without disturbing its structure, it can withstand up to 100 cycles of “thawing and freezing”. In addition to the fact that the dimensions of the ondulin sheet are convenient to use, it has a wide color palette.

The consumer still prefers this material, for the ability to bend up and down, which facilitates its installation on roofs with a curved surface.

In a word, ondulin is a universal roofing at a relatively low cost, but with a lot of positive characteristics in terms of installation and operation.

Did the article help you?