Cutting foam does not seem to be a difficult task, but to do it carefully, you need to have the skill and know some secrets. How and with what to cut foam at home and how to make a machine yourself to simplify this work? Now I'll tell you!

Styrofoam cutting

The scope of polystyrene foam is very wide. Parts for aircraft modeling are made from this material, it is used in the manufacture of toys and furniture, three-dimensional letters or sculptural elements for advertising are cut out of it, etc. We are interested in a very specific area - construction.

Types of cutting

In construction, foam plastic is used as a heater for roofs, walls, floors, ceilings, foundations and other structures. In the vast majority of cases, thermal insulation consists of expanded polystyrene sheets, which are sold in stores and have standard sizes.

During the installation of sheets, they constantly need to be cut, and here the following cutting options are possible:

- Longitudinal. This refers to the case when you need to cut a sheet of foam along its plane, for example, into two parts. For example, to make two sheets 25 mm thick from one sheet 50 mm thick: neither a knife nor a hacksaw will help here;

- transverse. When it is necessary to cut a piece of the desired shape from a sheet, that is, you will cut perpendicular to the plane of the sheet itself. In this case, you can use a knife, saw and other similar tools;

- through. Often it is necessary to make holes in the thermal insulation layer for the entry of an electrical cable, pipe or other communications. With some skill, you can get by with a knife, but there are more effective tools that I will talk about;

- curly. It is used when the edge of the sheet needs to be cut according to a clearly defined pattern with curved lines and a complex profile. Here, a regular knife will not work, and you will need a special tool.

Cutting tool

Styrofoam cutting can be done with a variety of tools. Most popular:

- construction knife. During insulation work, a knife is most often used to cut sheets. It can be a construction, stationery or shoe knife. The main thing is that it is well sharpened. The knife is carefully drawn along the cut line, strong pressure is not needed. If the sheet is not cut through, it is broken along the slot;

- Hacksaw. For cutting thick sheets, it is convenient to use a hacksaw for metal or wood with a fine tooth. Sold special saws for foam;

- Nichrome wire. A piece of thin nichrome wire is heated by passing an electric current through it. Fixed in a certain way and stretched, a hot string cuts the foam like butter;

- Thermoknife. In fact, this is a soldering iron, the tip of which is made in the form of a knife blade. The blade heats up and perfectly cuts any plastic, including foam;

- Laser ray. Styrofoam can be cut with a laser. This technology is used in the production of sculptural elements or in large-scale production for cutting a wide variety of shapes.

In construction, cutting of even rectilinear shapes is most often required, which the knife can handle quite well. A thermo-knife is ideal in this case.

If you need longitudinal cutting in thickness, a nichrome string is best suited.

How to make a nichrome wire cutter

How to cut styrofoam in thickness? This question often arises before the builder when it is necessary to dissolve the insulation sheet and make it thinner. For these purposes, a nichrome wire cutter is suitable.

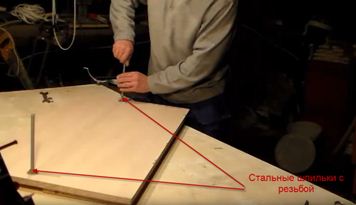

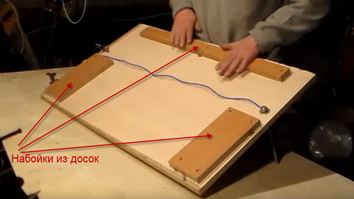

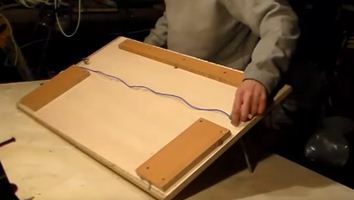

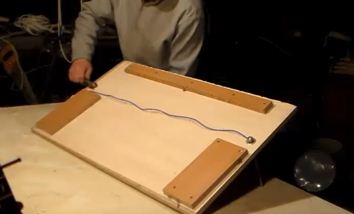

The idea of the machine is quite simple: a string is pulled over a tabletop made of board or plywood, through which a current is passed. The string is set horizontally at the required height, heated by the current and cuts the sheet, which the cutter moves along the tabletop.

Making such a machine with your own hands is quite simple:

Conclusion

I think now you understand how and how foam is cut. There are different ways and tools, choose the one that suits your particular case. To better understand the topic, watch the video in this article and ask questions in the comments if you have any.

Did the article help you?