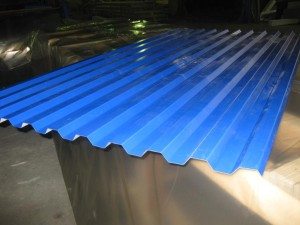

Weight of corrugated board - 1m2 is less than five kilograms, which is one of the main positive qualities of this material. This article discusses the main benefits of low weight, as well as the parameters of some specific grades of this material.

Decking is made in the form of thin sheets of metal with longitudinal recesses extruded with the help of special rollers, having one of the following shapes:

Decking is made in the form of thin sheets of metal with longitudinal recesses extruded with the help of special rollers, having one of the following shapes:

- Wave;

- Rectangle;

- Trapeze.

This material has a fairly high rigidity, which does not allow it to sag, deflect and vibrate, so structures with its use have sufficient strength in space without requiring additional installation of frames.

Another important quality that corrugated board has is a weight of 1m.2 quite small, which also significantly reduces the load on the foundation.

Advantages of corrugated board related to weight

The main advantages of corrugated board include the following:

- Weight 1m2 corrugated board does not exceed five kilograms (for comparison, the weight of one square meter of natural tiles can reach 42 kg);

- High strength and long service life, and the manufacturer's warranty for this material in some cases is up to ten years;

- Low weight 1 m2 corrugated board also provides significant savings in material, used for the construction of a supporting frame;

- Decking has an aesthetic appearance, and a wide range of models with different types of coating and profile shapes allows you to implement the most daring design and architectural solutions;

- The low weight of the material, as well as well-chosen standard dimensions (for example, with a width of 1200 mm and a thickness of 0.5 mm, the material - C8 corrugated board weighs only 4.9 kg) greatly simplify and speed up the installation procedure. In addition, the use of the lightest galvanized corrugated board allows you to abandon the use of special equipment for lifting loads.

The high popularity of this material is also due to its low weight. So, when reconstructing an old roof, C8 corrugated board, whose weight is significantly lower than the weight of asbestos cement sheets, significantly reduces both labor and financial costs for strengthening and replacing the rafter system.

At the same time, the rather low price of corrugated board makes it often the only option when choosing a material for roofing, as there are various types of corrugated board.

Important: for both roofing and wall corrugated board, the price and weight primarily depend on the thickness of the steel sheet from which it is made. For example, with a sheet thickness of 0.5 m, the weight of one square meter of corrugated board will be 3.8 kg, and with corrugated board weight at 17.17 kg, the thickness of the steel is 1 millimeter. In addition, the weight of the corrugated board is influenced by the height of the wave and corrugations, as well as the quality of the alloy. Modern technologies make it possible to produce steel with high strength at a lower weight, therefore, when choosing a corrugated board, it is desirable to clarify the composition and characteristics of the steel used in its manufacture.

Characteristics of various brands of corrugated board

Different brands of corrugated board are different, for example, the weight of corrugated board HC 35 differs from H75, etc. For clarity, consider the parameters of some brands of corrugated board:

- The H60 professional flooring possesses the increased rigidity and durability. The roofing sheeting it is used in roofing works and when covering fences, barriers and walls of non-residential premises, as well as ceilings between floors as a permanent formwork (marking H means "bearing"). This brand of corrugated board has a stiffening rib along its main part, which makes it possible to use it in the presence of high wind loads and as a supporting roof structure during the construction of a roof. H60 is also used on roofs with a slight slope and in the construction of large industrial buildings. To protect against external influences, sheets of H60 corrugated board are coated with galvanization and a layer of polymer coating that also protects the material from the negative effects of annual and daily temperature changes.The weight of H60 corrugated board with a thickness of 0.7 (0.8 or 0.9) mm and a sheet width of 1250 mm is 7.4 (8.4 or 9.3) kg for a running meter, for a square meter - 8.8 (9 .9 or 11.1) kg.

- H75 is a corrugated board used in the construction of roofs of both residential buildings and large industrial buildings. This material is highly durable, and the structural shape and thickness of the sheet allow it to withstand severe loads for a long period. This type of corrugated board is also used in the construction of vertical or horizontal planes that are constantly under load - for example, planes between floors or formwork. Due to the galvanization and polymer coating, the H75 is practically free from the negative effects of such factors as rain, snow and chemicals. With constant static and dynamic overloads on a large surface, this profiled sheet is not subject to deformation, and its service life is several decades. This makes H75 corrugated board fully suitable for the construction of large industrial facilities. The weight of H75 corrugated board with a thickness of 0.7 (0.8 or 0.9) mm and a sheet width of 1250 mm is 7.4 (8.4 or 9.3) kg for a running meter, for a square meter - 9.8 (11 .2 or 12.5) kg.

- The C21 professional flooring is made of sheets of galvanized high-quality steel. To give it increased rigidity, trapezoidal grooves or corrugations are molded over the entire area of the sheets. This material is used in various types of work, the main of which are the manufacture of fences and partitions.C21 sheets are characterized by high rigidity, which prevents sagging and deflection, and the structure as a whole has high strength, without requiring the installation of additional elements and a frame. Installation work is further simplified by the large area and low weight of the material sheet. The weight of C21 corrugated board with a thickness of 0.55 (0.7) mm and a sheet width of 1250 mm is 5.9 (7.4) kg for a running meter, and 5.9 (7.4) kg for a square meter.

- Profiled C8 - sheets of metal, the profile of which is a corrugation in the form of a trapezoid. The height of the material profile is 8 millimeters, and the height of the gutter is taken as the minimum. This material is used in the construction of various walls and partitions, fences and other lightweight structures, for example - it is a fairly economical choice for building a fence around a suburban area. Profiled sheet C8 is not used in the construction of roofs and load-bearing structures, and its main advantages over other materials are increased strength and relatively low cost. The weight of C8 corrugated board with a thickness of 0.55 (0.7) mm and a sheet width of 1250 mm is 5.91 (7.4) kg for a running meter, and 4.92 (6.17) kg for a square meter.

- S-10 and S10-1100 corrugated sheets are made of 01-grade galvanized sheet metal or polymer-coated galvanized steel. The height of the profile of this material is 10 millimeters, and the width is 1180 mm (working is 1150 mm), the steel density is 7800 kg / m3. The weight of C10 corrugated board with a thickness of 0.4 (0.5) mm and a sheet width of 1180 mm is 4.29 (5.26) kg for a running meter, and 3.63 (4.46) kg for a square meter.

- For the manufacture of corrugated board grades NS35 and NS35-1000, galvanized sheet metal grade 01 or 220-350 is used, as well as galvanized steel coated with polymers. The working width of such a sheet is 1000 mm, and the total width is 1060 millimeters. The weight of C10 corrugated board with a thickness of 0.4 (0.7 or 0.8) mm and a sheet width of 1000 mm is 4.4 (7.4 and 8.4) kg for a running meter, for a square meter - 4.19 (7 .04 or 7.9) kg.

Not all grades of corrugated board are listed above, the range of grades of this material is much more diverse. It should only once again be noted the low weight of the material, which allows its installation quickly and quite simply, without using special equipment.

In addition, a wide selection of different profiles and color shades allow using this material to implement almost any design and architectural solutions, giving a residential building or any economic or industrial building a unique and attractive appearance that will last for many years.

Did the article help you?