In private houses, very often the attic staircase is located outside the house, which at times limits the use of the premises under the roof, so some tend to make a hatch to the attic with their own hands from the side of the room. This greatly facilitates communication between floors, but at the same time requires the arrangement of an additional mechanism - a folding or sliding ladder.

Below we will talk about how this is done, and also, as an addition, watch the thematic video in this article.

Installation work

- When it comes to attic fire hatches or they are meant as communication passages, this means a hole with a lid, and sometimes even with a sliding ladder built into it. But stairs, this is a topic for another article, and we are interested in a hole with a lid and they can be considered as two separate devices, although they are interconnected.

- The fact is that the cover itself will completely depend on the hole made in the ceiling, while the perimeter of the opening, in turn, is made in accordance with the steepness of the stairs. If such a device is made during the construction of a building, then its parameters are included in the design calculations, but if you have to make a tie-in, then you need to do such calculations yourself. Detailed instructions for such work on concrete floors will be given below.

Hole in concrete floor

Recommendation. For the safety of work and the least weakening of reinforced concrete floors when cutting an opening, this is best done at the junction of the plates, as can be seen in the photo below, and not in the middle of one of them.

In order to tell how regular (for communication) or fire hatches to the attic are made, we chose concrete ceilings as the most durable material. Despite the fact that concrete is a very strong material, especially if it is reinforced, as in our case, nevertheless, a full-fledged hole can be made in just 1-1.5 hours.

For this, of course, you will need good tools, such as a grinder with discs for metal and concrete (with diamond coating) with a diameter of at least 220 mm, a hammer drill, a crowbar and a small sledgehammer.

Everything, of course, starts with the markup, and it is more convenient to do it from the top side of the plates, so we need to outline the desired perimeter with chalk. In order for the edges of the opening to turn out to be strictly vertical, we need a puncher with a drill that is longer than the thickness of the ceiling.

Install the puncher in a strictly vertical position (you can even use a level for this) and drill a through hole in each corner of the perimeter - they will serve as a guide for the lower marking of the floor.

Now you need to cut lines along the perimeter from above and below with a diamond disk, but we do it so that it does not reach the reinforcement, otherwise you will simply spoil the coating - it will burn out. When the slots are ready on both sides, find the voids with a perforator - for this, just drill through the plate. .

After you have found them, take a sledgehammer and break the weakest (thinest) places, and in those areas where the concrete rests on the reinforcement, it is best to beat it with a crowbar - the perforator drill will slip off.

When all the concrete is knocked down, you need to cut the reinforcement, but you need to do this flush or even crashing into the body of the slab with a disk so that the metal does not interfere with the installation of the hatch frame in the future.

You should also use a diamond-coated disc to level out all the irregularities that will definitely remain on the edges. Please note that a clear opening will contribute to the correct installation of the entire structure.

Recommendation. If you are purchasing sliding (folding) attic ladder from the manufacturer, then the passport may indicate either the desired size of the opening, or the size of the sliding (folding) block.

If in your case the second option is chosen, then keep in mind that the opening for attic hatches (finished blocks) is made 10 mm larger in each direction.

Lid with frame

So if you decide to buy folding or sliding attic ladder, then the question of how to insulate the attic hatch disappears by itself, since you will certainly choose a special design with thermal insulation.

Along with this, the assembly of the frame itself with the lid will automatically disappear - they are already ready and equipped with all mechanisms for smooth closing and opening. It remains only to make an opening in the ceiling correctly and in size, but this has already been discussed above.

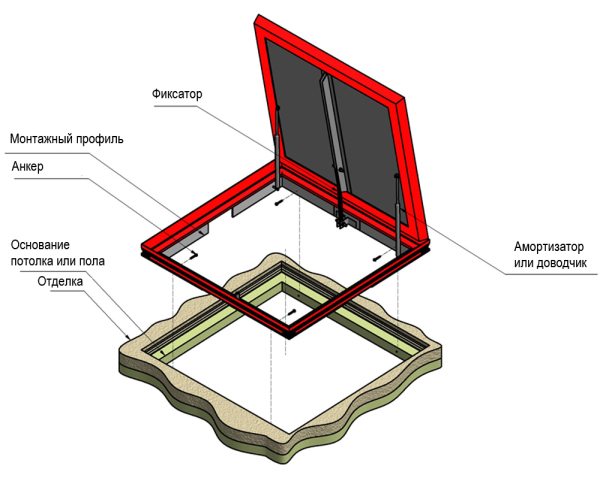

The question arises somewhat differently when you do everything yourself, then you will need a frame that needs to be fixed with anchors at the ends of the opening and a lid equipped with closers for smooth closing and opening. Most likely, your lid will open down, so it should be flush with the final finish of the ceiling.

Also, it is very likely that you will need an insulated attic hatch, then the thermal insulation should be located on top of the cover and be invisible to the view from the room.

In such cases, it is most convenient to use extruded polystyrene foam panels of the desired thickness and close them on top of fiberboard or some kind of plastic. At the same time, the foam panel must be cut according to the internal size of the frame, leaving a few millimeters of margin so that the insulation does not rub when closing, but also does not leave a large gap.

Conclusion

By and large, attic hatch for stairs - the matter is simple, but here it is very important to accurately maintain all dimensions so as not to leave gaps for drafts. The whole structure will not cost you too much, since its price will mainly consist of the cost of materials (metal and wood), although high-quality fittings (hinges and closers) will probably cost you more than a hatch.

Did the article help you?